Patternless Edger

LEXCE plus Trend8/Trend

Features

- Versatility to meet a broad range of needs

- Proven high-quality finish

- Effortless operation and superior serviceability

Detailed Information

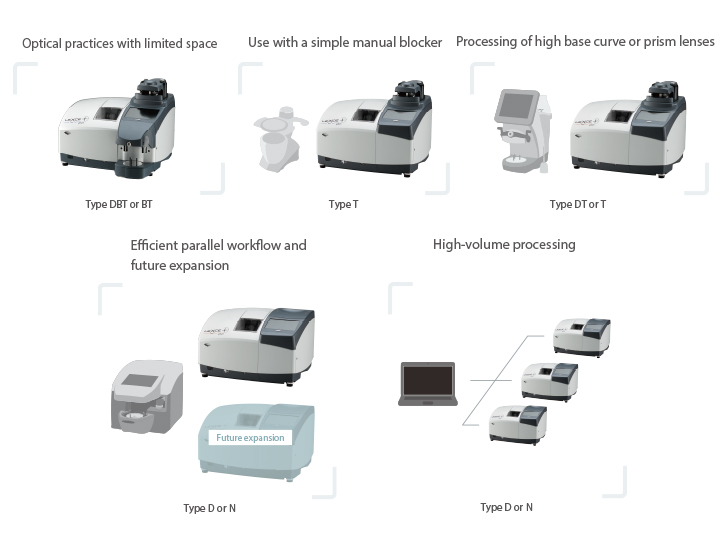

Versatility to meet a broad range of needs

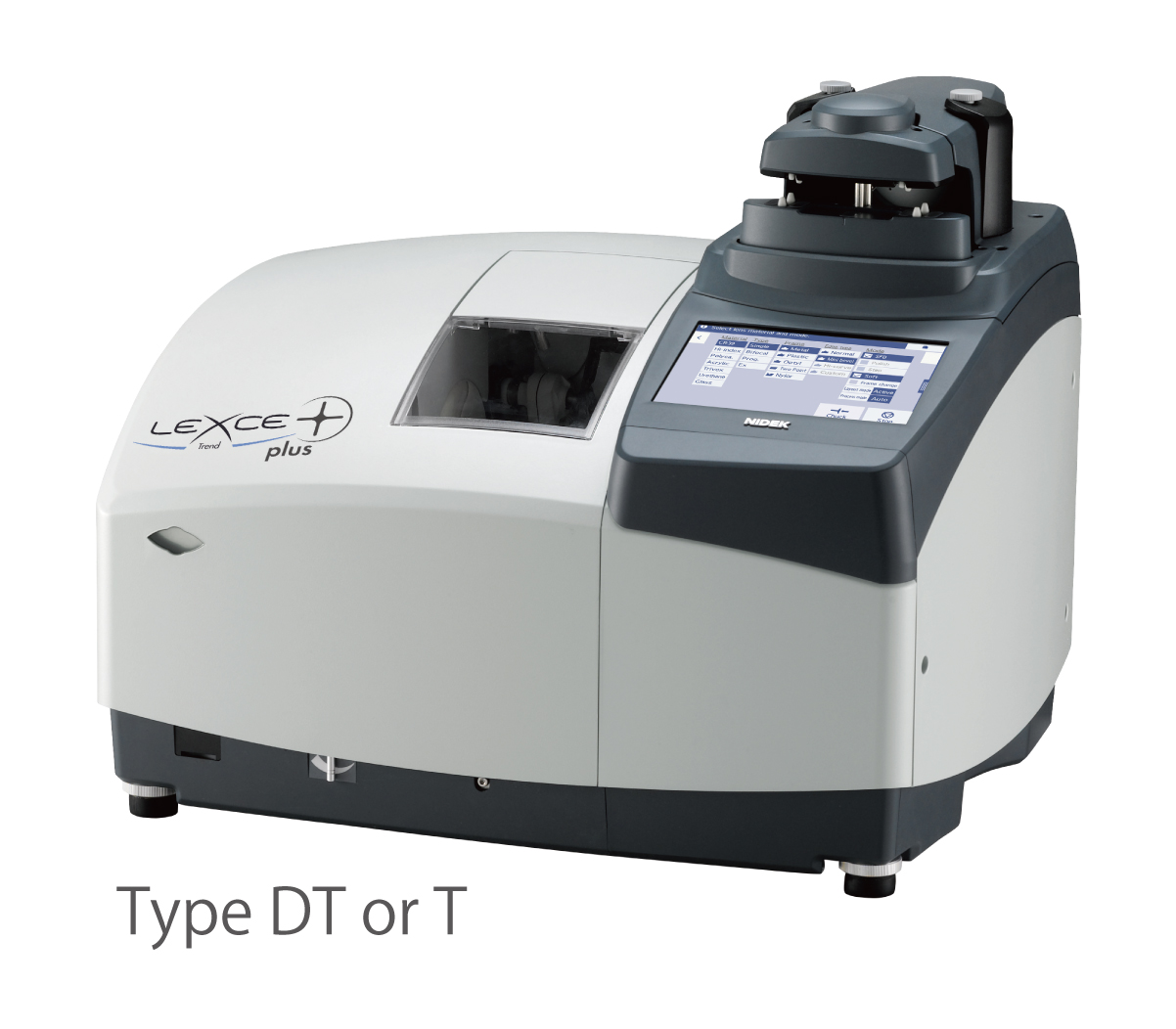

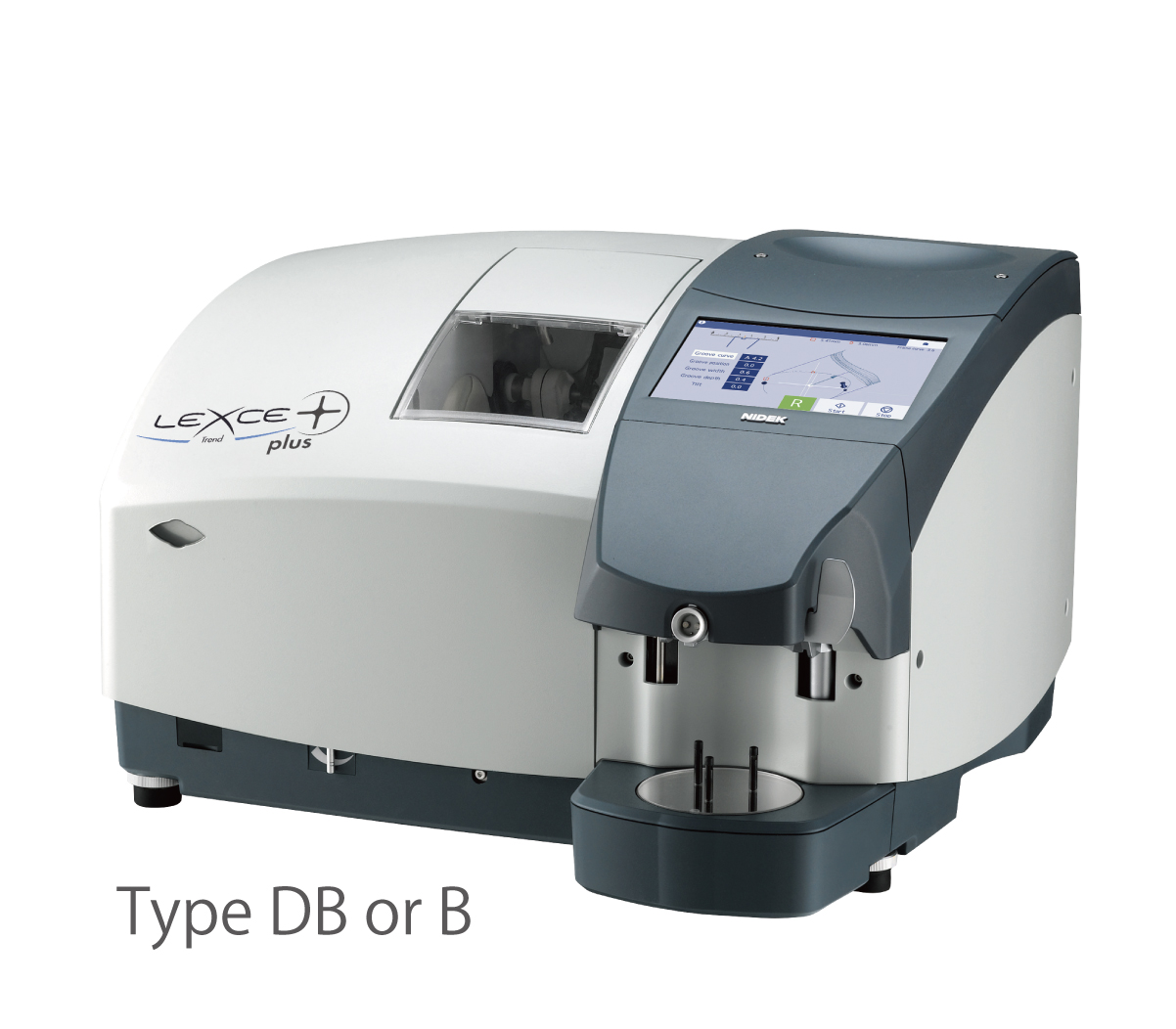

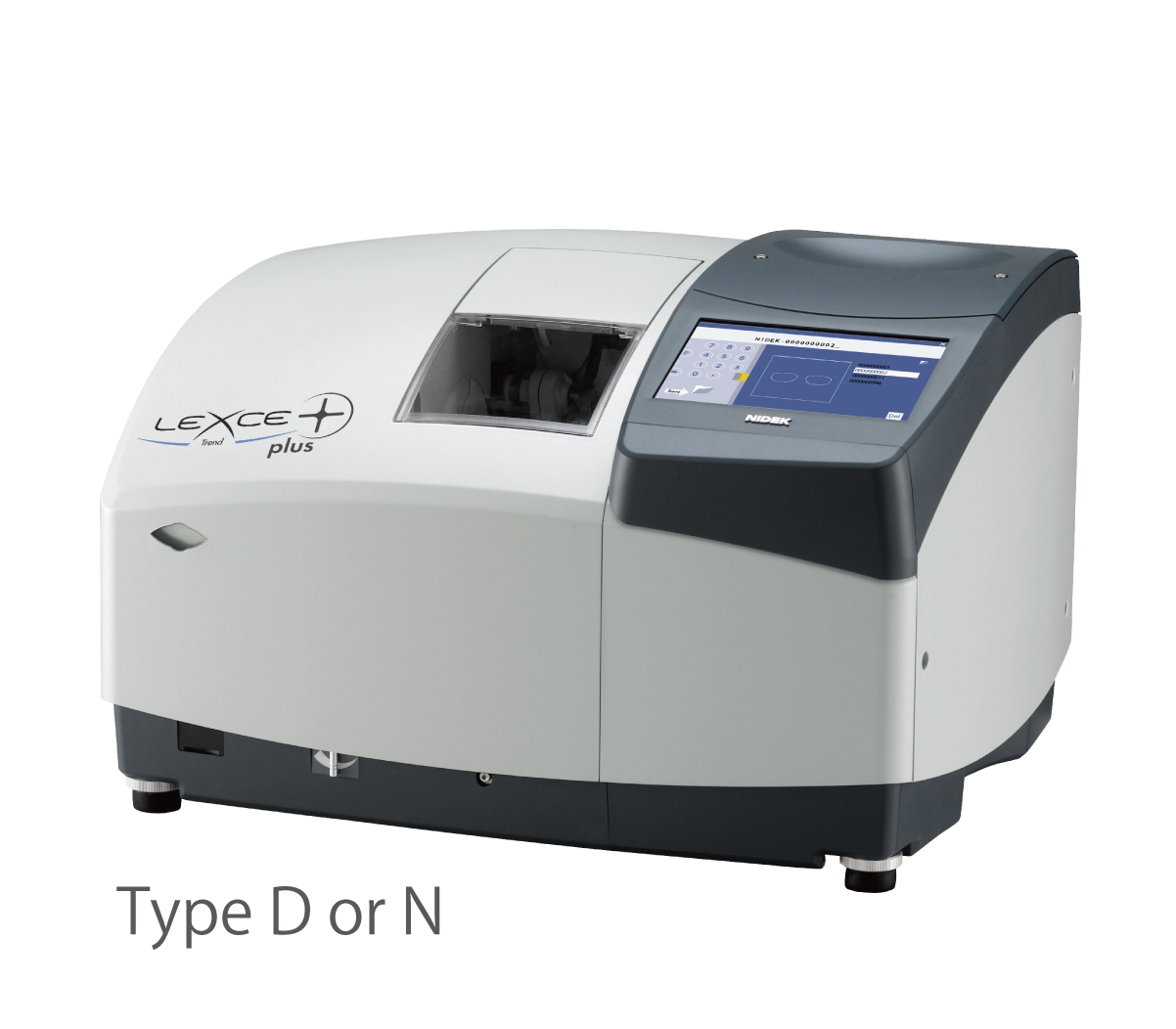

With a wide range of model configurations and peripheral equipment combinations, the LEXCE plus Trend8/Trend offers tailored solutions to suit your specific workflow. Whether you are processing just a few jobs or handling about 80 jobs in a standard 8-hour day, it delivers the scalability and performance to match your pace.*

*Processing speed may vary according to lens types, processing conditions, and the condition of your device.

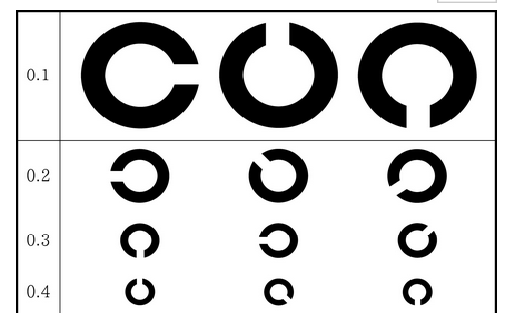

Proven high-quality finish

High base curve bevel*

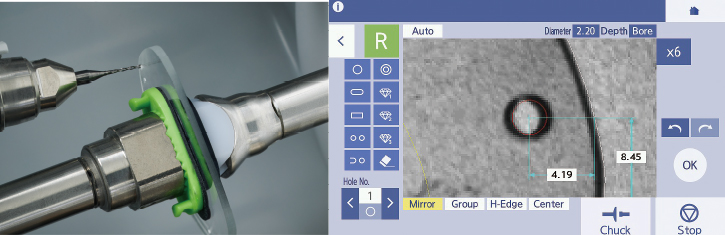

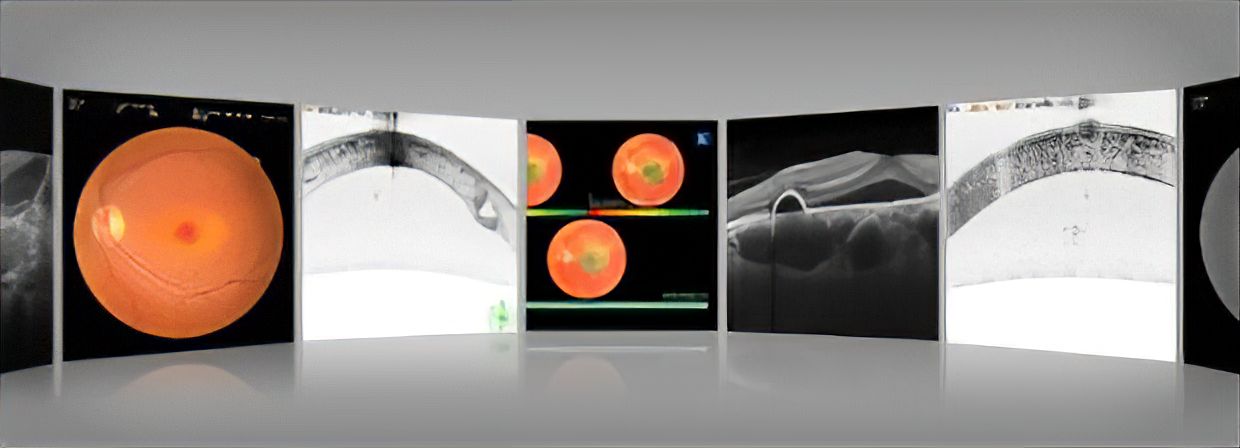

3D drilling optimally controlled by 5-axis

Axis stability

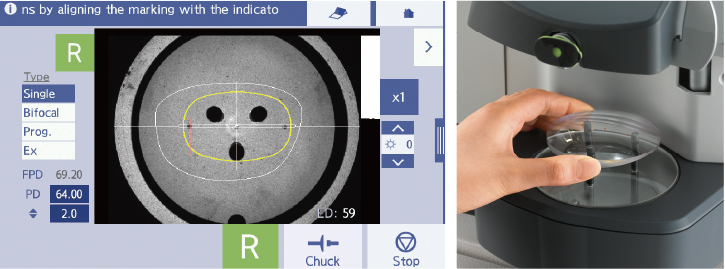

Intelligent blocker

3D frame tracing with full auto clamping (optional)

| Binocular measurement of 1,000 points per eye enables accurate measurement. Even high curve frame measurement is possible.

|

|

Effortless operation and superior serviceability

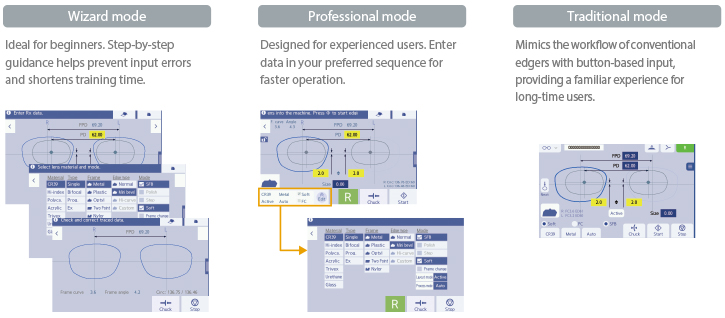

Selectable user interface

A 7-inch color LCD touch screen offers an intuitive and user-friendly interface through three selectable operation modes:

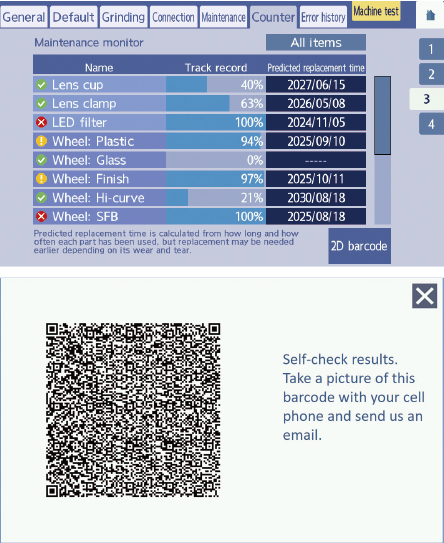

Superior serviceability

Downloads

Related Products

NOTE

The availability of products differs from country to country depending on the status of approval.

Specifications and design are subject to change without notice.

TOP

TOP