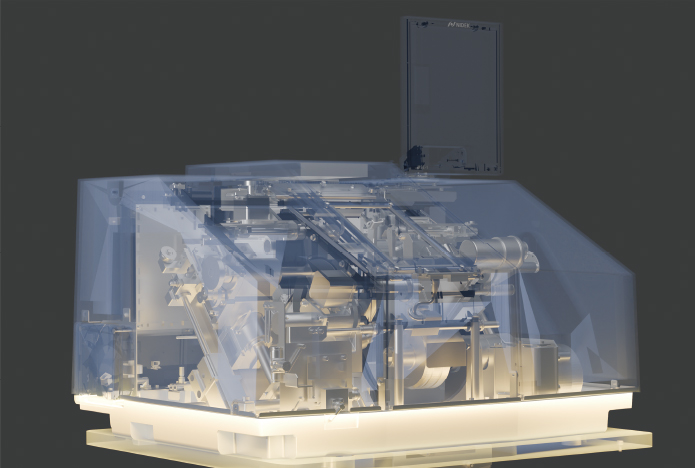

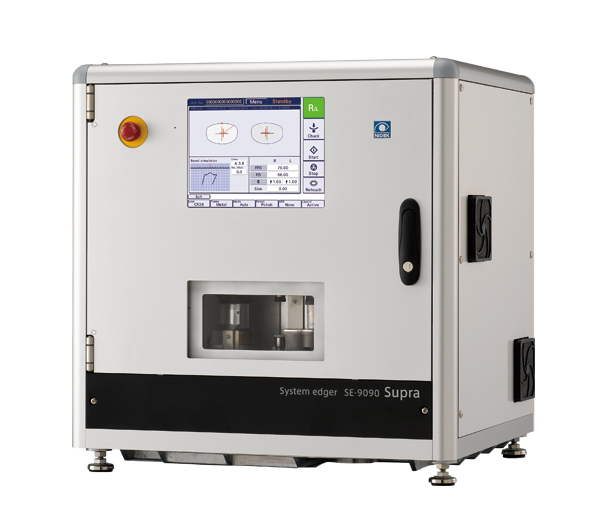

System Edger

MSE-1

Features

- High-speed and high-accuracy

- Extensive edging capabilities

- High-performance design for your optimal results

- Ideal for both labs and retails

Detailed Information

High-speed and high-accuracy

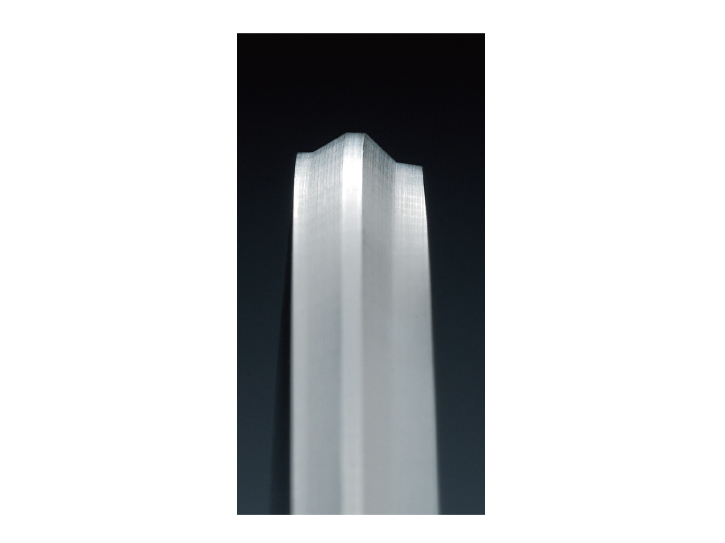

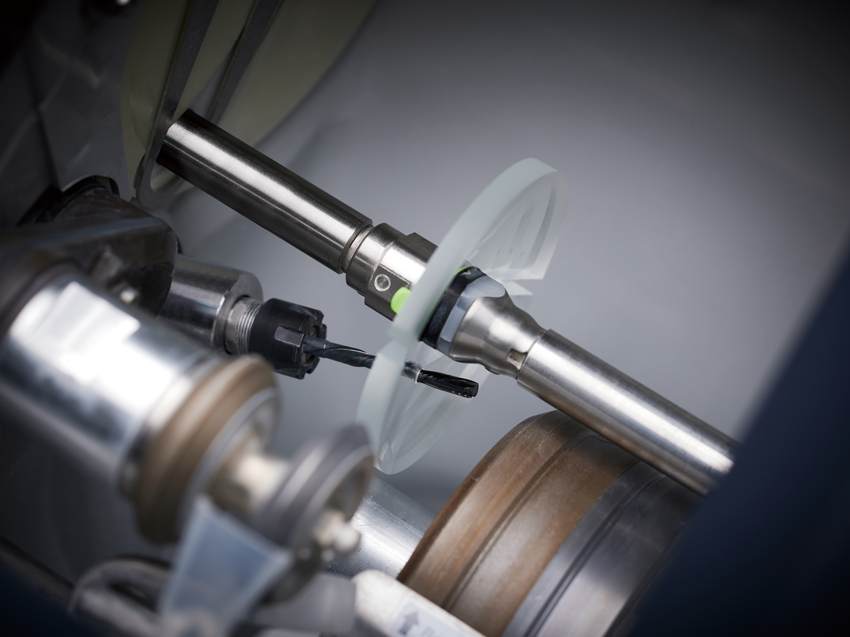

Hybrid edging with a milling tool and grinding wheels

Its hybrid edging system pairs a milling tool with grinding wheels for efficient, accurate processing.

・Roughing with a milling tool significantly reduces processing time

The MSE-1 features a high-speed spindle custom-engineered for NIDEK, optimized to deliver powerful performance in a compact body. Its rapid rotation enables fast rough cutting, significantly improving lens processing speed.

・High-precision finishing achieved with grinding wheels

The MSE-1 delivers high-speed edging without compromising accuracy. Unlike systems that rely solely on a cutter, it uses precision grinding wheels for the finishing process, ensuring consistently accurate results. Backed by NIDEK’s proven grinding technology, it offers reliable performance you can count on.

|

|

|

|

Extensive edging capabilities

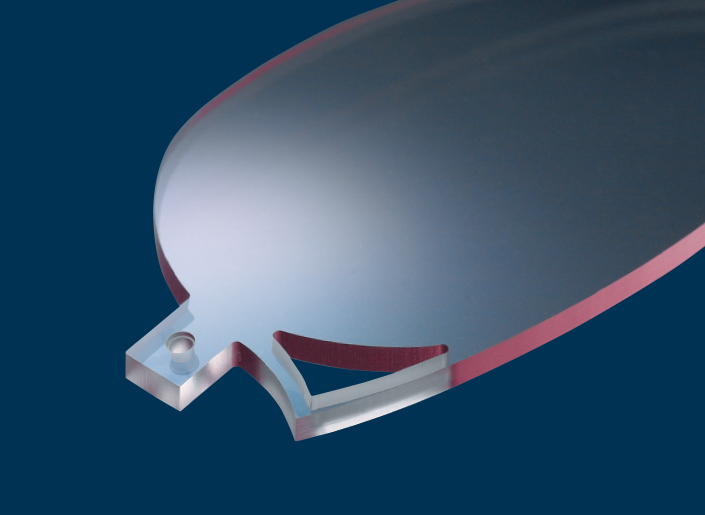

Step / partial step beveling and design cut

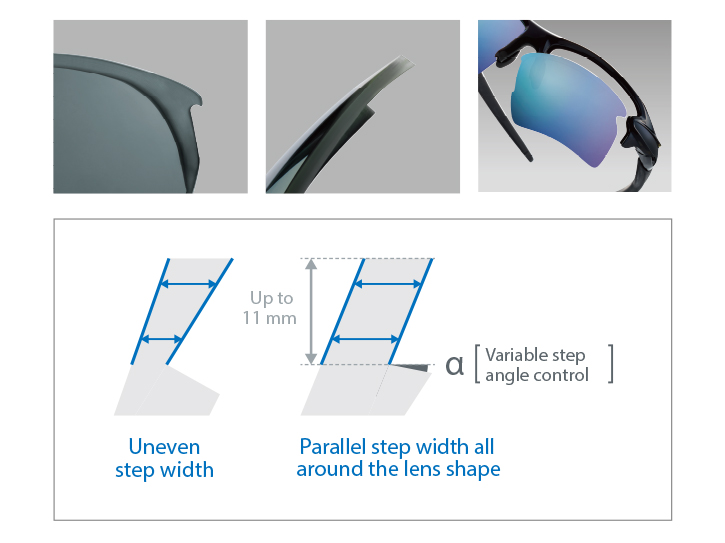

・Step / partial step beveling

Step beveling makes it easy to fit Rx lenses into sunglass and sport frames. Partial step beveling allows for precise application in designated areas, making it ideal for specialty sport frame designs. With support for lens sizes up to ø90 mm and step heights up to 11 mm, the MSE-1 handles even the most demanding bevel requirements with ease. To further enhance precision, the MSE-1 features variable step angle control, which maintains a uniform step width across the entire lens shape. This prevents the base of the step from becoming thinner, which leads to a consistent accurate fit, even in complex frame geometries, delivering professional-grade results with every lens.

・Design cut

The MSE-1 supports the processing of creatively designed lenses, including complex designs such as hook-shaped sports sunglass lenses, expanding what’s possible in lens finishing.

|

|

|

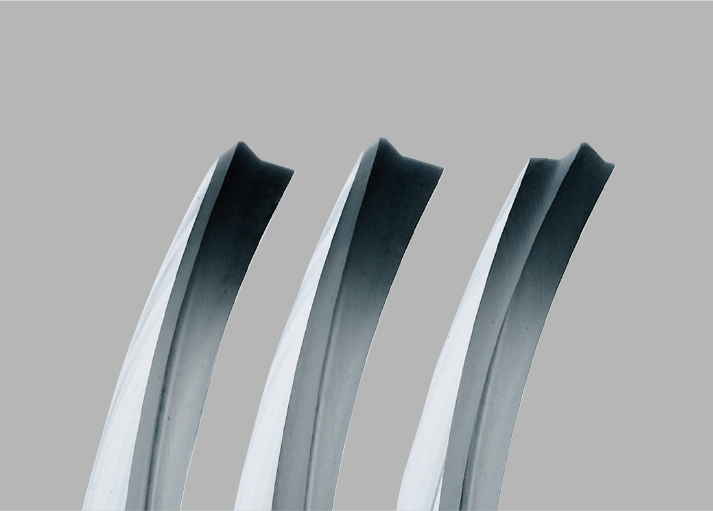

Custom beveling

Trapezoidal beveling enhances both the appearance and fit of lenses, particularly in sport and specialty frames. The heights of the front and rear bevels, along with the width of the bevel apex, can be precisely adjusted for optimal results. |

Automatic 3D drilling

The MSE-1 supports a wide range of hole shapes, including slots, notches, counterbored, and jewel holes, providing flexibility for detailed, customized lens work. |

|

|

High-performance design for your optimal results

Downloads

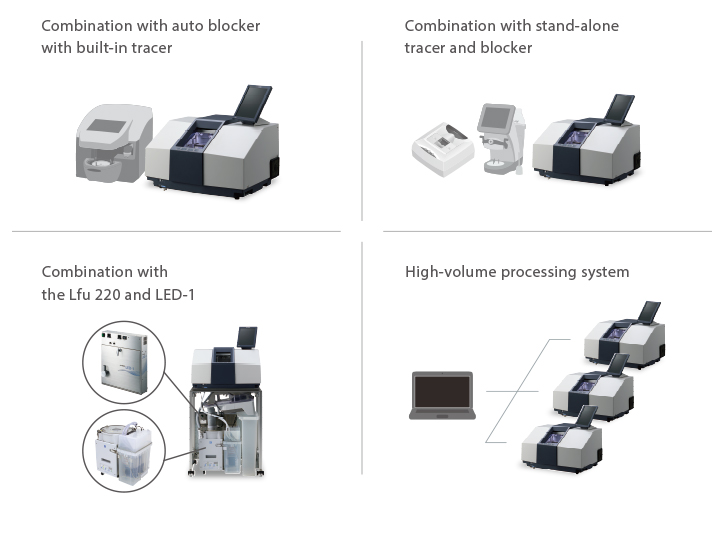

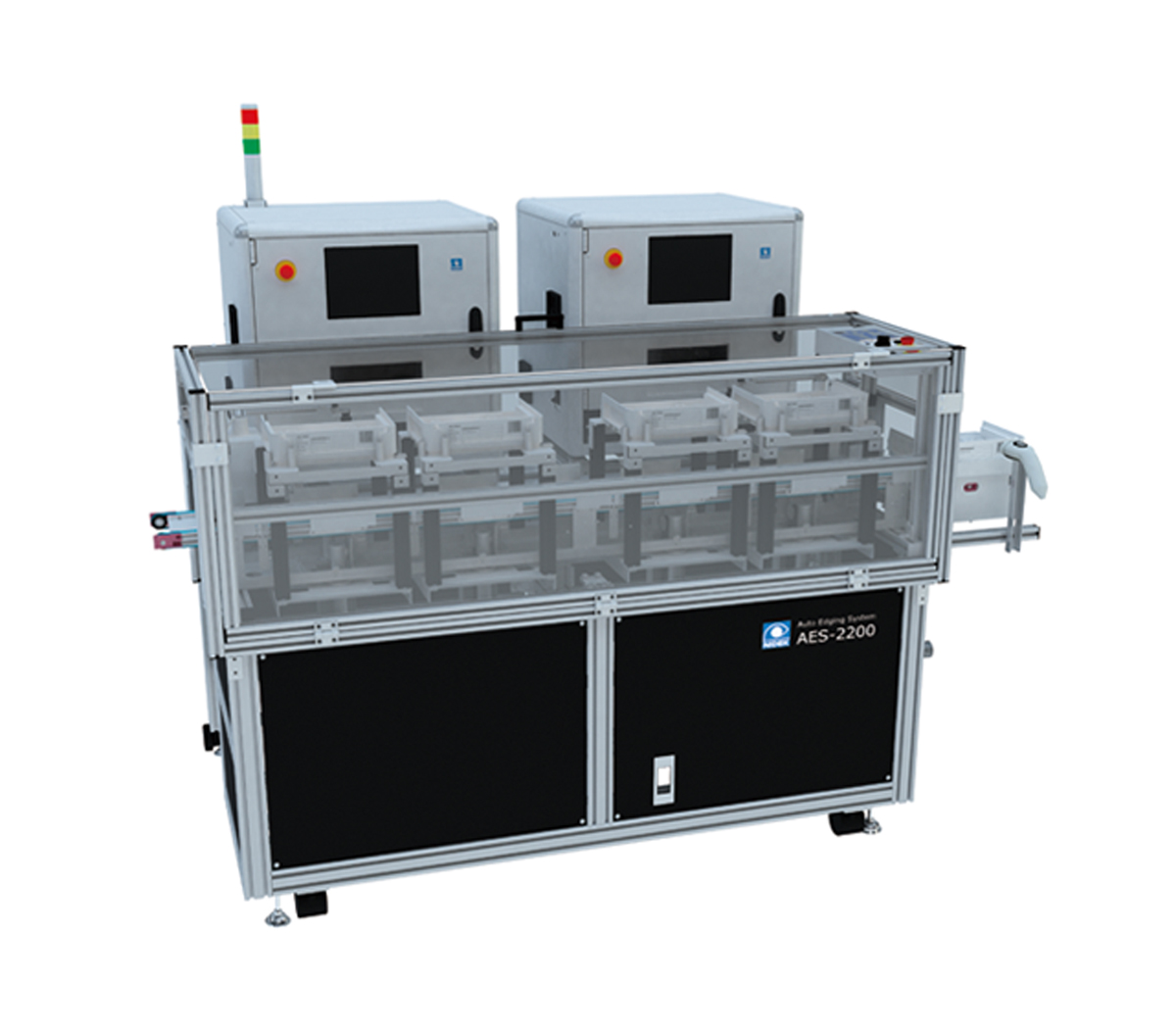

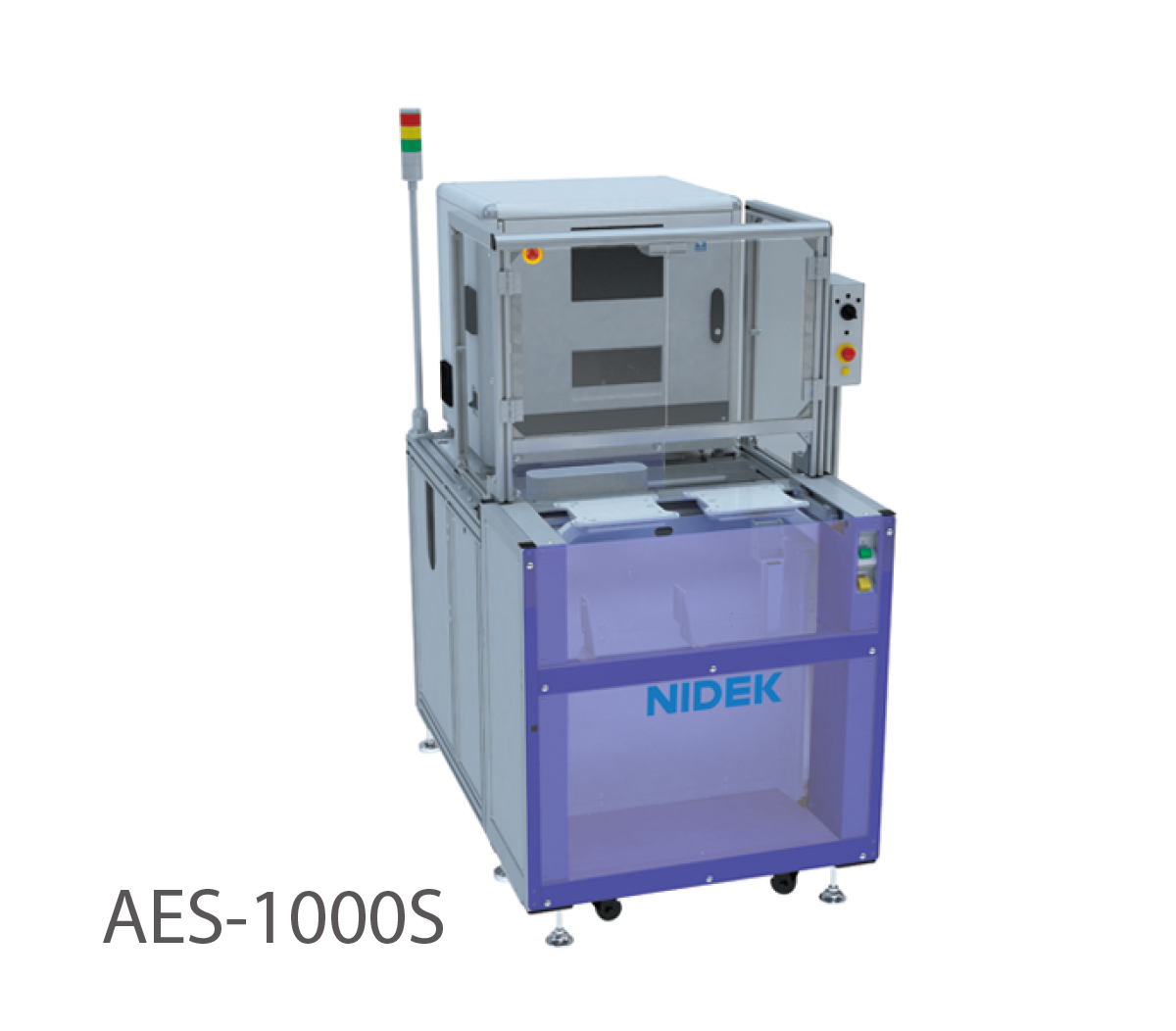

Related Products

NOTE

The availability of products differs from country to country depending on the status of approval.

Specifications and design are subject to change without notice.

TOP

TOP