Anti Reflective Coating, “Lequa-Dry”

-Standard AR Coating-

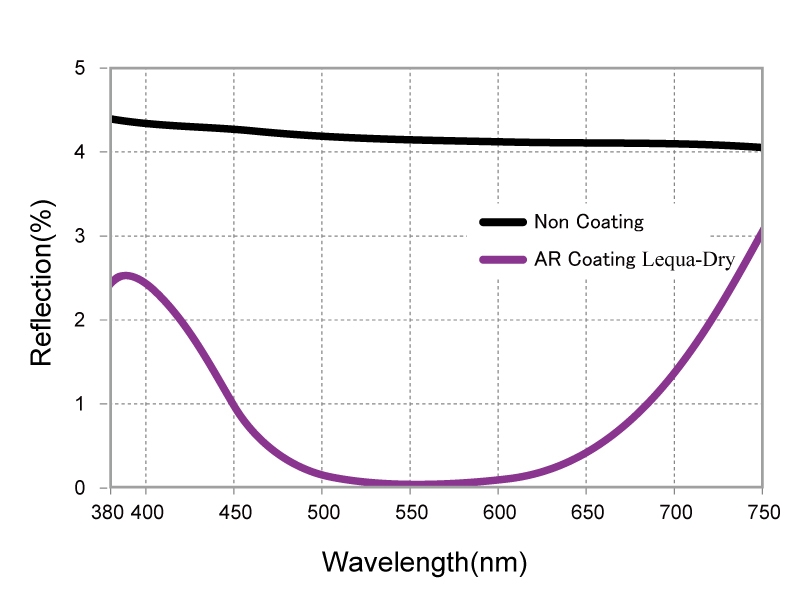

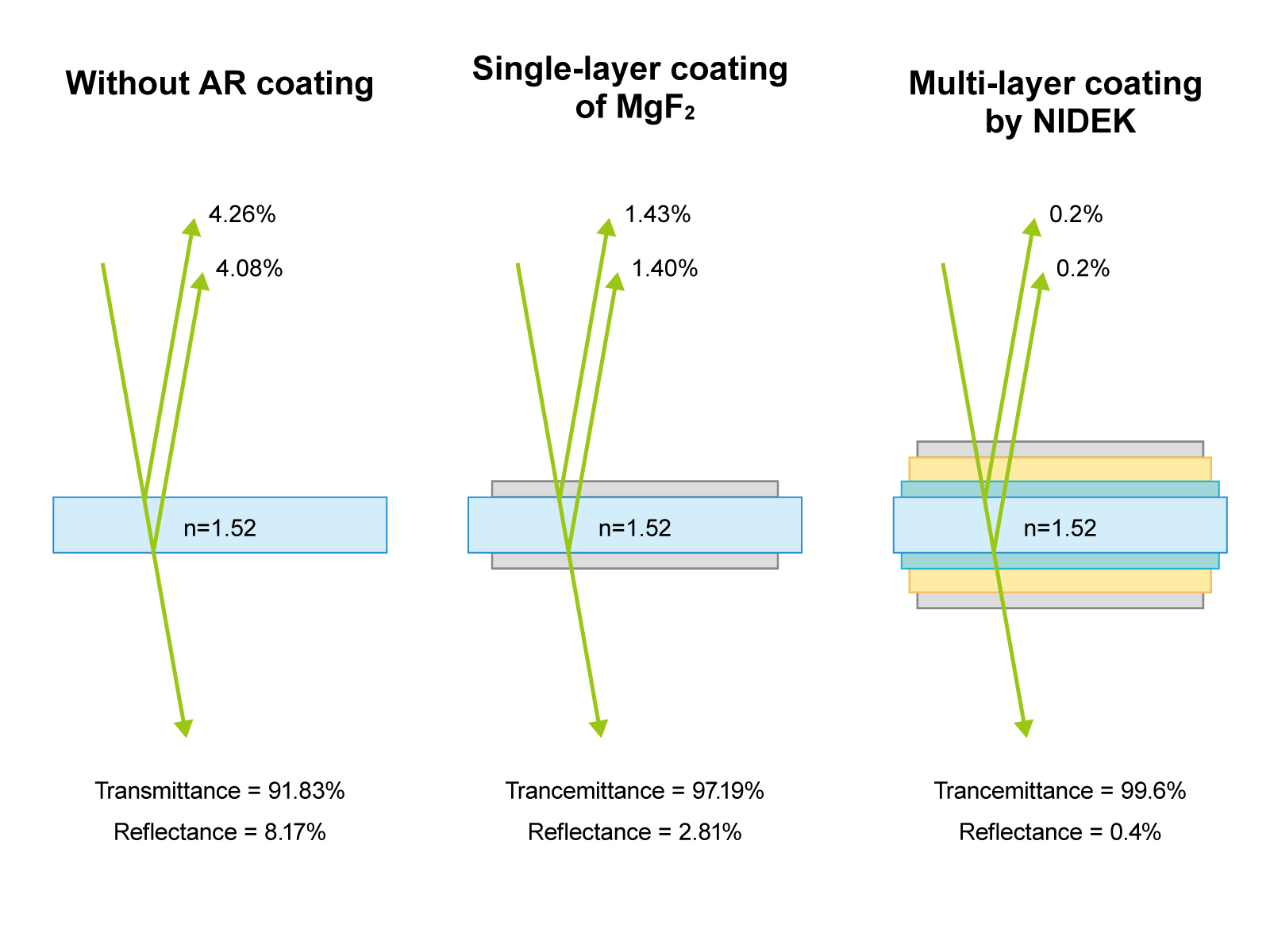

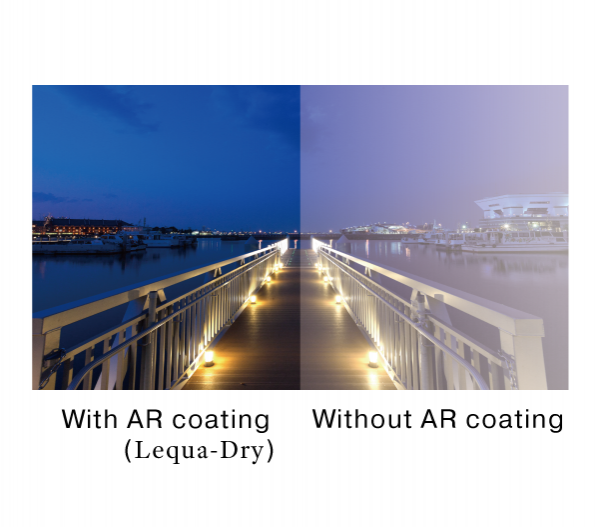

Reduce Light Reflection and Maximize Transmittance

Features

- Anti-reflective coating produced with vacuum deposition method

- Applicable to Glass, PMMA, PET and various lens materials

- Customizable spectral properties on request

- The largest producing capability by the larger sized vacuum deposition coating machine in the thin film industry

Detailed Information

Physical Properties

| Item | test condition and method | Results |

|---|---|---|

| Scratch Resistance | Steel wool #0000, 1.5 kg load, 5 strokes | 15 scratches or less |

| Pencil Hardness | JIS K5600-5-4 (750 g load) | 4H |

| Water Contact Angle | θ/2 method | 105° or more |

| Adhesiveness | Crosshatch tape test (3 times) | Pass |

Substrate : Hard coated PMMA with 2 mm thick

*The data in the table are for reference, not guaranteed value.

Applications

Brochure Request

For inquiries and brochure requests, please contact the following URL.

https://www.nidek-intl.com/contact/

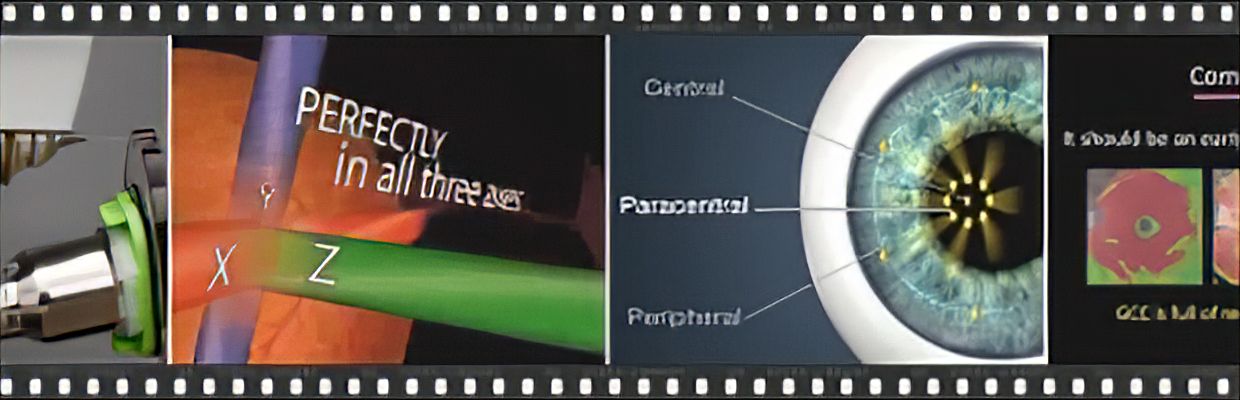

Coating Method (Vacuum Deposition)

Introduce our coating technology simply. These coatings are applicable to plastics, glasses, etc., wide range of substrates. Please consider applying our coatings on your own products.

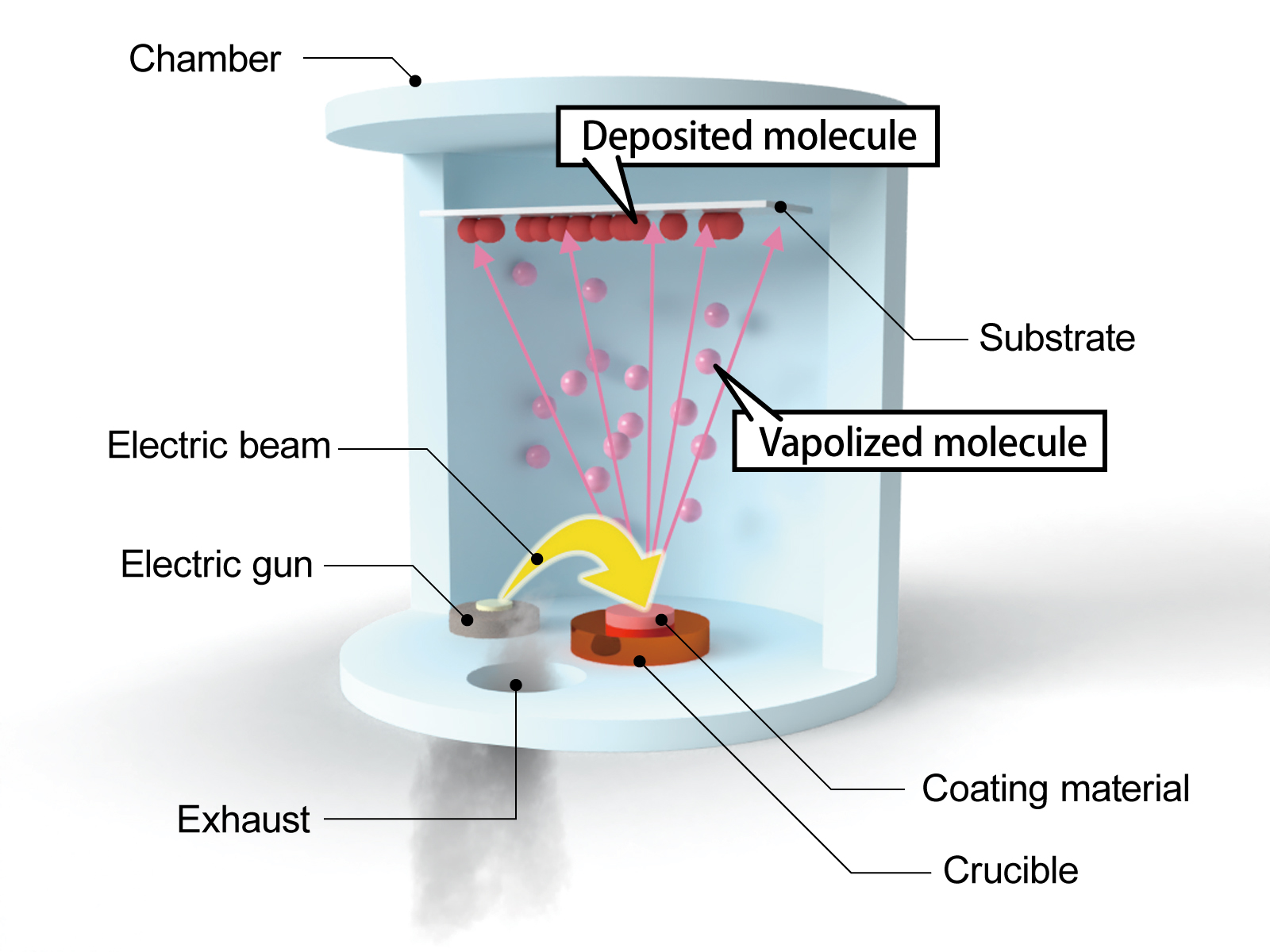

Vacuum Deposition Method |

Principle of Vacuum Deposition

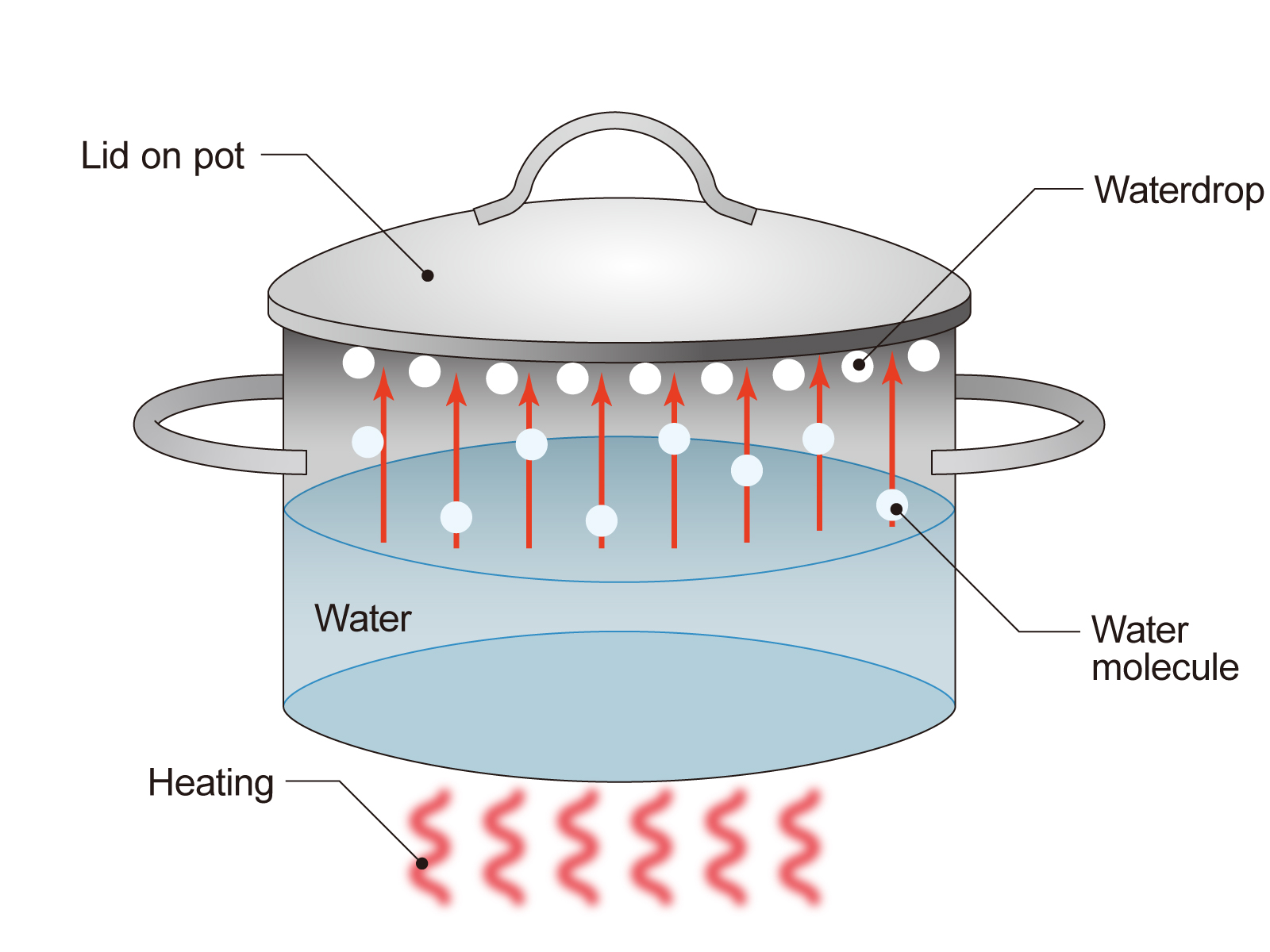

It is the same image that waterdrop is stuck on a lid when water in a pot is heated. The phenomenon that water vapor is stuck is applied to the technology of vacuum deposition. If the coating material were heated and vaporized by electric gun etc., the air would block the vaporized coating material from reaching to substrate. To apply the vaporized coating material on substrate, the coating material is vaporized in the vacuum environment, and it is the vacuum deposition method. Our products, Lequa-Dry and RefColor are applied by vacuum deposition method.

Coating Type (Anti Reflection Coating - AR Coating)

Introduce our coating technology simply. These coatings are applicable to plastics, glasses, etc., wide range of substrates.

Please consider applying our coatings on your own products.

Anti Reflection Coating (AR Coating) |

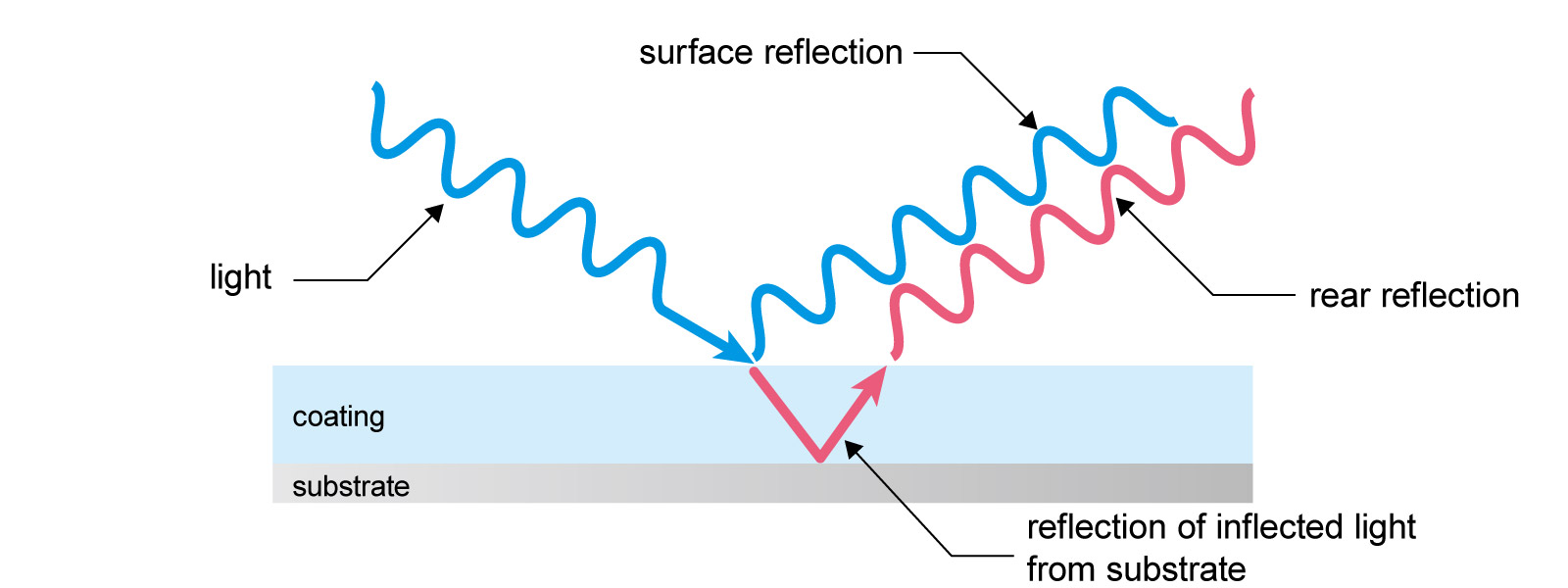

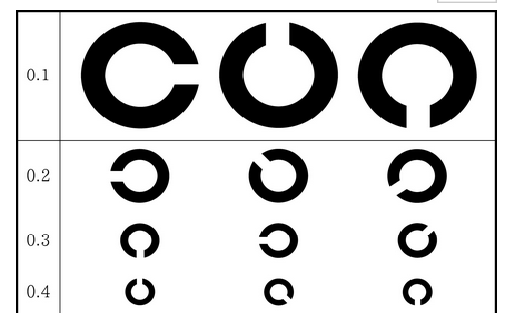

Principle of Anti Reflection Coating

Anti Reflection Coating is called as “AR Coating”.

It is the coating to reduce the reflection upon surface of plastic and glass by interference* of lights.

The suitable coating to each substrate and the customized coating to meet the requirement from customers are available.

*interference : phenomenon that light wave is enhanced and reduced each other by overlapping.

Anti reflection function occurs by offset of each wave of lights.

Examples of Anti reflection coating effect

Related Products

NOTE

The availability of products differs from country to country depending on the status of approval.

Specifications and design are subject to change without notice.

TOP

TOP